Influence of oxide layers on the plastic properties of metals

In an oxygen-rich environment, an oxide layer usually forms on metal surfaces. For the correct description of dislocation nucleation, the influence of oxidation must therefore be taken into account. This is particularly relevant for materials with a large surface-to-volume ratio such as porous structures and oxygen-affine metals such as aluminum. With the latter, an oxide layer forms within seconds, even under high vacuum conditions. This can strongly influence the mechanical properties of materials, which is partly due to increased dislocation formation due to an increased activation volume for dislocations and an increased number of nucleation sites. For nanocrystalline metals, this results in increased ductility.

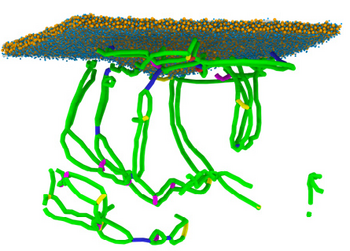

In this DFG-funded project, the influences of oxidation on the plastic properties of metals are to be studied using molecular dynamics simulations, taking into account the fundamental dependencies on oxygen concentration and temperature. The focus is on dislocation nucleation, taking into account oxide layers. The transition from increased ductility on the nanoscale to increased fracture probability on the mesoscale as a function of the thickness and morphology of the oxide layer will be investigated. The atomistic simulations will be used to implement the effects of nucleation on oxidized surfaces in mesoscopic dislocation simulations for thin films using a stochastic model. The aim is to implement a physically reliable model of dislocation simulation of oxidized surfaces that works on time scales comparable to experimental results.

Key Research Insights

Mechanical Property Alterations

Many different sets of molecular dynamics simulations and examinations have shown that nanoscale oxide layers have an impact on the mechanical properties of aluminum and titanium. The oxide layer on both of the assessed materials exhibits brittleness. Oxide layers have been shown to affect the overall mechanical characteristics of titanium and aluminum by modifying the nucleation process and preventing dislocation migration. On the other hand, aluminum nanofoams and nanowires that have undergone oxidation exhibit a substantial enhancement of Al-O bonds resulting in increased ductility.

Transition to Mesoscale

In this work, we examined the indentation and nanoscratching method as case studies. We analyzed various instances and materials, including high-entropy alloys at the nanoscale scale, using molecular dynamics simulations. On top of that, we employed the Discrete Dislocation Dynamics Simulations approach to build related models. In high-entropy alloys, the size of twinned regions in the plastic zone is greatest for the individual elements, but reduces for the alloys. We demonstrate that the chemical compound has a substantial impact on the buildup of dislocations.

Publication list

- D. Thürmer, O. R. Deluigi, H. M. Urbassek, E. M.Bringa, N. Merkert. Atomistic Simulations of the Shock and Spall Behavior of the Refractory High-Entropy Alloy HfNbTaTiZr. High Entropy Alloys & Materials, DOI: 10.1007/s44210-024-00042-2, 2024.

- K. C. Le, S. L. Dang, H.-T. Luu and N. Gunkelmann. Thermodynamic dislocation theory: Application to bcc-crystals. MSMSE 29(1): 015003, 2021, DOI: 10.1088/1361-651X/abcb4e.

- H. Song, N. Gunkelmann, G. Po und S. Sandfeld. Data-mining of dislocation microstructures: concepts for coarse-graining of internal energies. MSMSE 29:035005, 2021, DOI: 10.1088/1361-651X/abdc6b.

- H.-T. Luu, S. Raumel, F. Dencker, M. Wurz and N. Merkert. Nanoindentation in alumina coated Al: Molecular dynamics simulations and experiments. Surf. Coat. Tech. 437:128342, 2022, DOI: 10.1016/j.surfcoat.2022.128342.

- S. Homann, H.-T. Luu, N. Merkert. Molecular dynamics simulations of the machining of oxidized and deoxidized titanium work pieces. Results Surf. Interfaces 9:100085, 2022, DOI: 10.1016/j.rsurfi.2022.100085.

- I. A. Alhafez, M. Kopnarski and H. M. Urbassek. Scratching a soft layer above a hard substrate. Philosophical Magazine, 2023, DOI: 10.1080/14786435.2023.2212983.

- I. A. Alhafez, M. Kopnarski and H.M. Urbassek. Multiple Scratching: An Atomistic Study. Tribol Lett 71: 46, 2023, DOI: 10.1007/s11249-023-01718-3.

- A. Demirci, D. Steinberger, M. Stricker, N. Merkert, D. Weygand und S. Sandfeld. Statistical analysis of discrete dislocation dynamics simulations: initial structures, cross-slip and microstructure evolutions. MSMSE 31:075003, 2023, DOI: 10.1088/1361-651X/acea39.

- I. A. Alhafez, O. R. Deluigi, D. Tramontina, C. J. Ruestes, E. M. Bringa and H. M. Urbassek. Simulated nanoindentation into single-phase fcc FexNi1-x alloys predicts maximum hardness for equiatomic stoichiometry. Sci Rep 13(1):9806, 2023, DOI: 10.1038/s41598-023-36899-3.

- I. A. Alhafez, O. R. Deluigi, D. Tramontina, N. Merkert, H. M. Urbassek and E. M. Bringa. Nanoindentation into a bcc high-entropy HfNbTaTiZr alloy – an atomistic study of the effect of short-range order. Sci. Rep. 14:9112, 2024, DOI: 10.1038/s41598-024-59761-6.