Research

Research

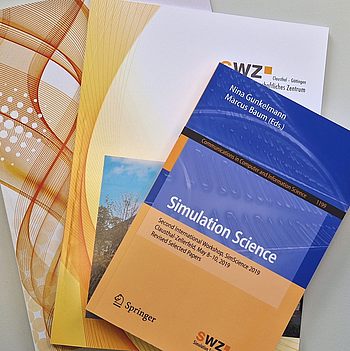

Simulation Science Center Clausthal-Göttingen (SWZ) is concerned with both the further development of simulation methods and their application in various areas of mathematics, computer science, physics and engineering.

Simulationsmodelle zur Beantwortung von konkreten Fragen werden in allen Bereichen der Industrie, der Wissenschaft sowie für viele gesellschaftliche Fragestellungen eingesetzt. Das SWZ erforscht und entwickelt dafür geeignete Methoden und Werkzeuge und bietet diese aktiv den jeweiligen Nutzern an. Dabei stehen einerseits empirische und modellbasierte Ansätze und andererseits datenbasierte Ansätze wie Methoden der Künstlichen Intelligenz und des High-Performance-Computings im Fokus.

Simulation models are used to answer specific questions in all areas of industry, science and for many social issues. The SWZ researches and develops suitable methods and tools for this purpose and actively offers these to the respective users. The focus here is on empirical and model-based approaches on the one hand and data-based approaches such as methods of artificial intelligence and high-performance computing on the other.

The current projects at the SWZ are divided into the areas shown below. The list of research areas represents a snapshot and can and will be supplemented by future projects.

-

By now simulation is one of the most important and in many cases the only viable technique for analysis and optimization of large networks. Telecommunication networks, traffic and logistic networks and energy networks have much in common. The complexity of the networks with its many parallel existing nodes and the flows between nodes is difficult to comprehend and often cannot be controlled with other techniques than simulation. The actual behavior of such a network is often different from the assumed behavior. The construction, operation, modification and optimization of such networks usually represent an infrastructure task that is associated with considerable costs. To avoid undesirable developments, simulation is used as an important tool to determine the properties of a network, the behavior of the critical performance characteristics and parameters at an early stage.

In the context of Industry 4.0, so-called digital twins, which can be used to analyse and optimize various aspects of real production both in the run-up to construction and commissioning and during operation, have now become established. As part of the research at the SWZ, the corresponding methods for modeling and simulating widely networked production and logistics processes are being further developed and tested in practice together with industrial partners.

-

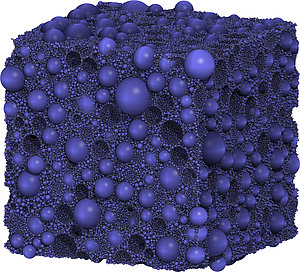

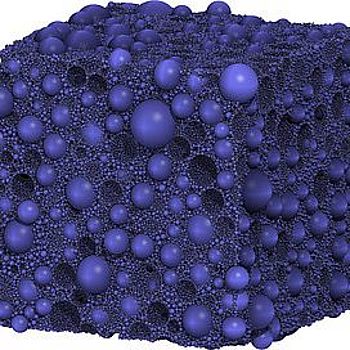

The advances in material science have always defined the state of development of a society. Material science is one of the key topics in the german industrial landscape which provides the basis for many innovations in other areas of industry.

In materials science, a highly interdisciplinary approach is already astablisched, which is divied into the strongly overlapping areas of "Computational Materials Science", "Computational Physics" and "Computational Chemistry". Simulations have developed into a living and research-oriented scientific branch in material science and their neighboring natural sciences, which is also increasingly perceived and actively promoted by the industry.

Problems in material sciences are very diverse and are typically based on multiple lengths and time scales. Therefore, the field of material simulations is characterized by a variety of different simulation methods, which are tailored to the respective problem class:

On the smallest scale, atomic processes are simulated parameter-free on the basis of natural laws in so-called ab-initio simulations. These quantum mechanics methods usually require high-performance computers, but allow to achieve a variety of quantitative results. Such a program package is developed and distributed in Clausthal.

On the macroscopic length scale, the material is considered to be a continuum whose behavior is determined by material parameters that are either known from an experiment or determined by more basic simulations. Since the simulation techniques are largely uniform here, particularly commercial program packages are used. The main interest here is the modeling of the problem and the determination of the parameters and equations as well as the verification and visualization of the results.

Between these poles, there are a number of other methods. Some will be listed as following: Monte Carlo methods, molecular mechanics, molecular dynamics, phase field theories, microstructural simulation of dislocation networks and grain boundaries.

Therefore one of the "Grand Challenges in Computational Materials Science" is the multiscale simulation, which ideally extends from ab initio simulation to the simulation of forming processes and manufacturing processes. On the one hand, this challenge is addressed by the fact that simulation parameters are deliberately transmitted from the microscopic simulations to the macroscopic simulations. On the other hand, different simulation methods are integrated into a uniform simulation environment in order to describe effects in which different length and time scales can no longer be decoupled. These activities require the cooperation of different scientific disciplines and benefit from mergers as planned at Simulation Science Center.

In contrast to several other applications of simulation methods, simulations in the field of material science are very often characterized by the fact that they have to exploit all available information processing resources to their limits in order to achieve usable results. Questions of algorithmic complexity and efficiency of implementations are therefore of crucial importance for the progress of the simulation methods in this area.

Since optimization and characterization of materials are associated with large amounts of data in various formats, artificial intelligence methods are increasingly being used for analysis. These methods can be used to generate synthetic data when analytics and conventional modeling reach their limits. In recent years, machine learning methods have therefore become established for predicting structure-property relationships and for material development. However, the predictive power depends on the availability of large data sets, which is why some aspects can still be better described by simulation. The SWZ contributes this expertise to various fields of application in materials science and engineering.

-

The real-time control of human-machine teams in manufacturing and in the service sector is mainly concerned with the coordination of plans and actions of team members during the joint processing and handling of individual operations. The focus here is on an integrated view of the efficiency of the overall socio-technical system and the satisfaction and safety of people.

Close collaboration between humans and machines requires that both human and machine members of a team have a common understanding of the actions performed.

Another important factor is trust in the collaboration partner - both from the human to the machine and vice versa. Only with trust can a reliability of behavior be achieved, whereby the full potential of a collaboration can be reached. People can only trust a machine if the machine is known to be well tested, just as collaboration between people is difficult if one of the participants has a bad reputation. Modeling trust from the machine's perspective is the overall measurable result of evaluating variables that describe the human condition and human behavior.

The design of interaction models for human-machine collaboration requires an interdisciplinary approach: both trust and intention models must be integrated and the interaction must be designed to be adaptable and with a high degree of automation in the engineering process.

A collaborative robot in a team should be able to recognize its human partner's trust in it and ensure that this human partner is not overconfident in its abilities and uses it for tasks it was not designed for. It should also prevent the partner from jeopardizing itself or the overall task. This reflects the need for dynamic trust calibration during human collaboration with an autonomous machine.

Capturing physiological parameters has proven to be well suited to derive information about human cognitive conditions and is highly relevant for assigning a confidence level. However, capturing such phenomena is limited not only by the level of acceptance and potential interference with human actions, but also by the monetary cost of instrumenting workplaces with the sensor infrastructure to capture the required data.

In order to make informed decisions, the machine must not only model the current state of the human teammate, but also make reliable short-term predictions about the teammate's actions, plans and even intentions. In this context, modeling and anticipating human body movements and walking paths are crucial. In addition to hand and head movements, arm movements are also important in the context of safe human-machine collaboration, e.g. during assembly or disassembly processes, as are people's walking routes.

Completed research projects

List of SWZ-funded projects that have been successfully completed in the meantime.

Clausthal-Göttingen International Workshop on Simulation Science

SWZ hosts the international conference "Clausthal-Göttingen International Workshop on Simulation Science".